SCOPE

In this article, we discussed the basic requirements of the American Society of Mechanical Engineering (ASME) and Boiler Pressure Vassel Code (BPVC) section-I.

The requirements of the Part general procedure (PG) applies to power boilers and high pressure, high‐temperature water boilers and liquid phase thermal fluid heaters and to parts and appurtenances thereto and shall be used in conjunction with the specific requirements in the applicable Parts of this Section that pertain to the methods of construction used.

SERVICE LIMITATIONS

👉2.1 The rules of this Section are applicable to the following services :

(a) boilers in which steam or other vapor is generated at a pressure of more than 100 kPa for use external to itself.

(b) high‐temperature water boilers intended for operation at pressures exceeding 1 .1MPa and/or temperatures exceeding 250 °F (12 0 °C )

👉2.2 For the services below those specified in 2.1 it is intended that rules of Section IV apply; however, boilers for such services may be constructed and stamped in accordance with this Section provided all applicable re- querulents are met.

👉2.3 Coil type hot water boilers where the water can flash into steam when released directly to the atmosphere through a manually operated nozzle may be exempted from the rules of this Section provided the following conditions are met:

(a) There is no drum, header, or other steam space.

(b) There is no steam is generated within the coils.

(c) Tubing outside diameter does not exceed 1 inch (2 5 mm).

(d) Pipe size does not exceed Nominal Pipe Size (NPS) 3 /4 (Nominal Diameter DN 20 ).

(e) Nominal water capacity does not exceed 6 gals (2 3 L).

(f) Water temperature does not exceed 3 50 °F (175 °C ).

(g) Adequate pressure relief valve s and controls are provided.

REFERENCED STANDARDS

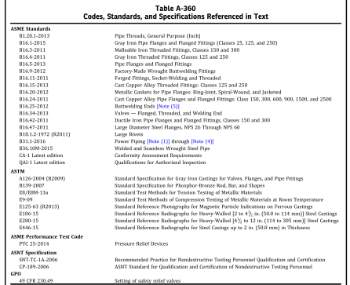

👉3. The Manufacturers shall establish the effective Code Editions, Addenda, and Code Cases for the boilers and replacement parts in accordance with the Mandatory Appendix VI. Specified conditions of standards referenced in this Section are shown in Table A-360.

UNITS

👉Either U.S. Customary, SI, or any local customary units may be used to demonstrate compliance with all requirements of this edition (examples, materials, examinations, inspection, testing, certifications, design, fabrications, and overpressure protection).

In general, it is expected that a single system of units shall be used for all the aspects of design except were unfeasible or impractical. When components are manufactured at different locations where local customary units are different from those used for the general design, the local units may be used for the design and documentation of that component. Similarly, for the proprietary components or those uniquely associated with a system of the units different than those used for the general designs, the alternate units may be used for the design and documentation of that components.

For any single equations, all the variables shall be expressed in a single system of units. When separate equations are provided for the U.S. Customary and SI units, those equations must be executed using the variables in the units associated with the specific equations. Data expressed in other units shall be converted to the U.S. Customary and or SI units for use in these equations. The results obtained from the execution of these equations may be converted to the other units.

Production, measurement, and test equipment, drawings, welding procedure specifications, welding procedure and performance qualifications, and other fabrication documents may be in U.S. Customary, SI unit, or local customary units in the accordance with the fabricator's practice. When values are shown in calculations and analysis, fabrication documents or measurement and test equipment are in different units, any conversions necessary for verification of Code compliance, and to ensure that dimensional consistency is maintained, shall be in accordance with the following:

(a) Conversion factors shall be accurate to at least four significant figures . 1 ASME BPVC .I-2017

(b) The results of conversions of units shall be expressed to a minimum of three significant figures.

Conversion of the units, using the precisions specified above shall be performed to ensure that the dimensional consistency is maintained. Conversion factors between U .S. Customary and S I units may be found in A - 3 9 1 through A-393 of Nonmandatory Appendix A. Whenever the local customary units are used, the manufacturers shall be provided the source of the conversion factors, which shall be subject to verifications and acceptances by the Authorized Inspectors or Certified Individuals.

Material that has been manufactured and certified to either the U . S. Customary or SI material specification (examples, SA-516M ) may be used regardless of the unit systems used in the design. Standard fittings (e .g . , flange s, elbows, etc. ) that have been certified to either the U.S. Customary or and the SI units may be used regardless of the unit system that is used in the design.

All entries on a Manufacturer’s Data Report and data for Code‐ required nameplate marking shall be in units consistent with the fabrication drawings for the component using U.S. Customary, SI, or local customary units. It is acceptable to show alternates unit parenthetically. Users of this Code are cautioned that the receiving jurisdictions should be contacted to ensure the units are acceptable.

MATERIALS

👉Except as otherwise permitted in the general procedure, PG-8. 2, general procedure, PG-8.3, general procedure, PG-10, and general procedure, PG-11, material subject to the stress due to pressure shall conform to one of the specifications given in ASME Section-II and shall be limited to those that are listed in the Tables of ASME Section-II, Part D. The Manufacturer shall ensure that the correct material has been received and is correctly identified before proceeding with construction (see A-302.4). Materials shall not be used at the temperatures above those for which the stress values are limited, for the ASME section-I. Construction, in the Tables of ASME Section-II, Part D. The specific additional requirements described in general requirement (PG)-5 through general requirement (PG)-1 3 shall be met as applicable.

PG-5 .2 Material covered by the specifications in Section II is not restricted as to the method of the production unless so stated in the specifications, and as long as the product complies with the requirements of the specifications.

If in the development of the art of the boiler constructions, it is the desired to use materials other than the those herein described, the data should be submitted to the Boiler and Pressure Vessel Committee (BPVC) in accordance with the requirements of Section II, Part D, and the Mandatory Appendix 5. Materials not completely identified with any approved Code specifications may be used in the construction of the boilers under the conditions outlined in General Procedure (PG)-10.

Size Limits and Tolerances.

👉 Materials outside the limits of size or and the thickness given in the title or scope clause of any specification in ASME Section-II, it may be used if the material is in compliance with the other requirements of the specifications, and no similar limitations are given in the rules for constructions.

The Pipe having a tolerance of ±1% on either the outside (O.D). or the inside (I.D.), rather than the tolerances specified in the material specifications, may be used, provided the materials comply with all other requirements of the specifications. When used under external pressure, such pipe shall be limited to a maximum of 600 mm in diameter. The pipe shall include the designation 1% outside (O.D.) or 1% inside (I.D.), as appropriate, in any required documentation and marking of the materials.

The use of austenitic alloy steel is permitted for the boiler pressure parts that are steam touched in normal operation. Except as specifically provided in PG-9 .1 .1, PG-1 2, PEB -5 .3, and PFE -4, the use of such austenitic alloys for boiler pressure parts that are water wetted in normal service is prohibited.

P-No. 15E, Group 1 Materials.

If during any phase of the manufacturing or erection any portion of the component that does not contains a weld is heated to a temperature greater than the 80 0 °C, one of the following actions shall be performed:

(a) The component shall be re austenitized and retempered in its entirety in accordance with the specification requirements.

(b) That portion of the component heated above 800 °C, including the heat‐affected zone created by the local heating, must be replaced or must be removed, austenitized, and re tempered in accordance with the specification requirements and then replaced in the component.

Quick links

What is Welding Procedures Specification (WPS) and its Process?

Welding (WPS) thickness limit.

What are 3LPE coating and its life?

Required mechanical/DT test for welder qualification (WQT).

Required mechanical/DT test for welding qualification (WPS).

(c) If the allowable stress values to be used are less than or equal to those provided in Section II, Part D, Subpart 1, Table 1A for Grade 9 (e .g. , SA-21 3 T9, SA-3 3 5 P9, or equivalent product specifications ) at the design temperature, then the requirements stated above may be waived, provided that the portion of the component heated above 800 °C is re-tempered in accordance with the specification requirements. The use of these provisions shall be noted on the data report of the Manufacturer.

If during any phase of the manufacturing or and erection of the components, any portions that do contains a weld is heated above the 785 °C, then the requirements of Notes (3 ) and (4 ) of Table PW-395 for P -No. 15E, Group 1 Materials, shall apply for the reheating treatment.

PLATE

👉Steel plates for any part of a boiler subject to pressure, whether or not exposed to the fire or products of combustion, shall be of pressure vessel quality in accordance with one of the following specifications:

dance with one of the following specifications:

Grade SA - 204, The Pressure Vessel Plates, Alloy Steel, Molybdenum.

Grade SA-240, (only 405 Type) The Pressure Vessel Plates, Alloy Steel (Ferritic Stainless), Chromium.

Grade SA-285, The Pressure Vessel Plates, Carbon Steel, and Low‐and Intermediate‐Tensile Strength.

Grade SA - 299, The Pressure Vessel Plates, Carbon Steel, Manganese‐Silicon.

Grade SA-302, The Pressure Vessel Plates, Alloy Steel, Manganese‐ Molybdenum, and Manganese‐Molybdenum‐Nickel.

Grade S A - 387, The Pressure Vessel Plates, Alloy Steel, Chromium‐Molybdenum

S A - 515, Pressure Vessel Plates, Carbon Steel, for Intermediate‐ and Higher‐Temperature Service.

SA - 516, Pressure Vessel Plate, Carbon Steel, for Moderate and Lower‐Temperature Services.

SA/AS 148, Fine-Grained, Weldable Steel Plates for Pressure Equipment.

SA/EN‐10028‐2, the flat Products Made of Steels for Pressure Purposes.

SA/G B 713, The steel Plates for the Boilers and Pressure Vessels code (BPVC).

SA/J IS G3 118, Carbon Steel Plates for Pressure Vessels for Intermediate and Moderate Temperature Service.

Post a Comment

Please do not enter any spam link in the comment box.